TYPE K THERMOCOUPLE (Chromel / Alumel)200°C to +1260°C / -328°F to +2300°F

Chromel {90% nickel and 10% chromium} Alumel {95% nickel, 2% manganese, 2% aluminium and 1% silicon}

Thermocouple Type K

This is the most common thermocouple type that provides the widest operating temperature range. Type K thermocouples generally will work in most applications because they are nickel based and have good corrosion resistance.

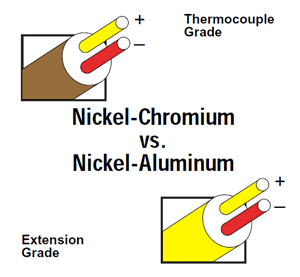

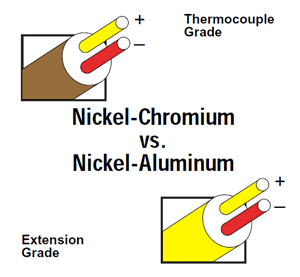

•1. Positive leg is non-magnetic (Yellow), negative leg is magnetic (Red).

•2. Traditional base-metal choice for high temperature work.

•3. Appropriate for use in oxidizing or inert atmospheres at temperatures up to 1260°C (2300°F).

•4. Vulnerable to sulfur attack (refrain from exposing to sulfur-containing atmospheres).

•5. Perform best in clean oxidizing atmospheres.

•6. Not recommended for use under partially oxidizing conditions in vacuum, or when subjected to alternating cycles of oxidization and reduction.

Composed of a positive leg, which is approximately 90% nickel, 10% chromium and a negative leg, which is approximately 95% nickel, 2% aluminum, 2% manganese and 1% silicon.Type K Thermocouples are the most common general purpose thermocouple with a sensitivity of approximately 41µV/°C, chromel positive relative to alumel. It is inexpensive, and a wide variety of probes are available in its -200°C to +1260°C / -328°F to +2300°F range. Type K was specified at a time when metallurgy was less advanced than it is today, and consequently characteristics vary considerably between samples. One of the constituent metals, nickel, is magnetic; a characteristic of thermocouples made with magnetic material is that they undergo a step change in output when the magnetic material reaches its Cure Point (around 354 °C for type K thermocouples).

Type K Thermocouple ( Chromel/Constantan)

Type K thermocouples usually work in most applications as they are nickel based and exhibit good corrosion resistance. It is the most common sensor calibration type providing the widest operating temperature range. Due to its reliability and accuracy the Type K thermocouple is used extensively at temperatures up to 2300°F (1260°C). This type of thermocouple should be protected with a suitable metal or ceramic protection tube, especially in reducing atmospheres. In oxidizing atmospheres, such as electric furnaces, tube protection is not always necessary when other conditions are suitable; however, it is recommended for cleanliness and general mechanical protection. Type K will generally outlast Type J because the JP wire rapidly oxidizes, especially at higher temperatures.

Temperature Range:

•Thermocouple grade wire, −454° to 2,300°F (−270 to 1,260°C)

•Extension grade wire, −32° to 392°F (0 to 200°C)

•Melting Point, 2550°F (1400°C)

Accuracy (whichever is greater):

•Standard: ± 2.2C% or ±.75%

•Special Limits of Error: ± 1.1C or 0.4%

Deviations in the alloys can affect the accuracy of thermocouples. For type K thermocouples the tolerance class one is given as ± 1.5 K between -40 and 375 °C. However, deviations between thermocouples coming from the same production are very small and a much higher accuracy can be achieved by individual calibration.

Metallurgical changes can cause a calibration drift of 1 to 2°C in a few hours, increasing to 5 °C over time. A special grade of Type K is available that can maintain special limit accuracy up to ten times longer than the regular grade.