RTD elements are used to manufacture temperature sensors. A resistance element is the temperature sensing component at the heart of an RTD or resistance thermometer. Typically, they cannot be used in their bare form, but may be built into a probe or assembly which will enable them to withstand various conditions of their application. Each has a pre-specified resistance value at a known temperature which changes in a predictable fashion. In this way, by measuring the resistance of the element, the temperature of that element can be determined from tables, calculations or instrumentation.

Thin film elements are mass produced by automated equipment which deposites a layer of platinum onto a ceramic substrate and uses a laser photolithography to etch an electrical current path corresponding to the required value in ohms. The elements are smaller than traditional wire wound elements and as a result have a faster response time and fit more applications, while reducing user costs at the same time.

Temperature sensors can be made with ceramic elements wounded on either ceramic or glass former, or a platinum wire helix can be semi-supported within the bores of a ceramic tube. This semi-supported type will provide the widest operation temperature range and typically the best stability.

The most common type is Platinum on either a Ceramic or Glass insulator. Nickel, Copper, Balco, MIL-STD temperature versus resistance curves are also available.

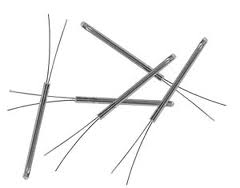

Thermometrics can add lead wires to the elements available in this catalog, per your specifications. Common additions are 20 awg, teflon coated nickel wire.

Wire wound glass (quartz)encased elements are available to meet your requirements.